- D.J. Laboratories Pvt. Ltd.

Infrastructure & Quality Assurance

Quality Assurance

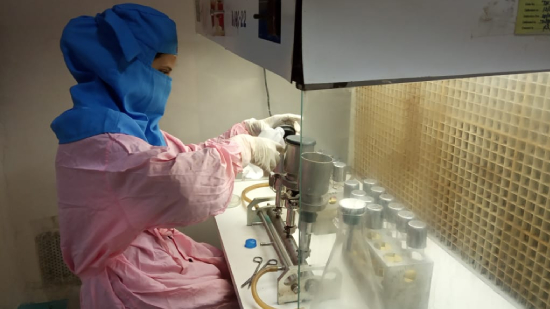

In order to make sure that the Intravenous Fluids and other high value Pharmaceutical Formulations are of optimum quality, we make sure that the raw material used is of the best quality and the end products are tested using computerized equipment. Zero-defect, sterile, triple distilled pyrogen-free water solution obtained from computerized “Multi Column” system is maintained at 80 degree C till the time of filling and sealing. In order to ensure quality, all the quality tests are performed religiously.

Due to the built-in flaw of technology, the polyethylene containers are filled at room temperature of 25 / 30 degree C. The solution is processed under optimum manufacturing practices such as titrations through 0.22 micron filters (German) USA made disposable membrane filters. It is made sure that the atmosphere is bacteria free and is performed under pressure by centrally air conditioning & Hepa filters thus maintaining positive air pressure purity up to 99.9%.

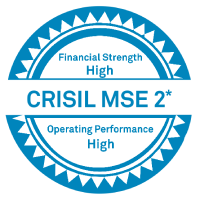

All our products are designed to meet the needs of W.H.O., G.M.P. and ISO-9002. Owing to the quality of our products, we have been awarded various certificates such as:

Export Certificate

G.M.P. Certificate

Revise Schedule ‘M’ Certificate

ISO Certificate

CRISIL Credit Rating SE 2B Certificate

Warehousing & Packaging

We have a huge warehouse spread over a vast area and has all the required facilities to store that products safely till the time of final dispatch. There are various shelves, so that the range is stored in an organized manner. Our storekeepers make sure that the products are duly labeled and numbered that ensures hassle free retrieval at the last moment. In addition to this, we also make sure that the products are packed in optimum quality packing material. With the help of this, our products are safe during the transportation.